HTKR Filling, Labelling & Packaging

HTKR PACKAGING MACHINES & AUTOMATIONS

The Packaging Hub

Our core expertise in End of Line Automation solutions are

We are in the packing industry for last 20 years with rich experience in all the areas of packaging - primary, secondary and treachery. We worked with many industrial verticals including Pharma, Packaging, Food & Beverage, FMCG, Metal, Plastic, Oil, Explosive etc.

Case Erector with gluing or bottom taping or both

Case Filling / Case Packing

Flap Closing & top taping

Palletizing

Conveying systems (variety of conveyors – belt, roller, chain link, plastic belt, telescopic etc) &

Automation

Brief About Our Activities

Bottle Rinser

Liquid / powder / cream Filler

Capper

Labeler

Case Packer

Carton Erector

Palletizer

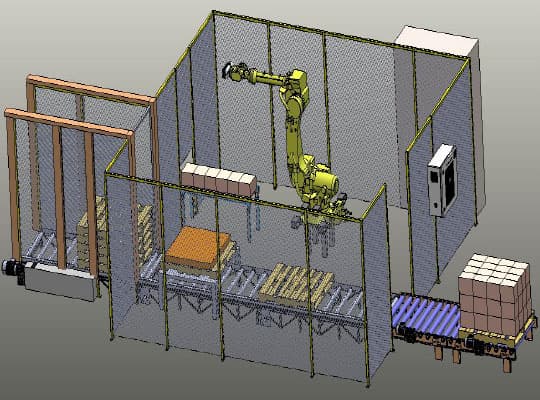

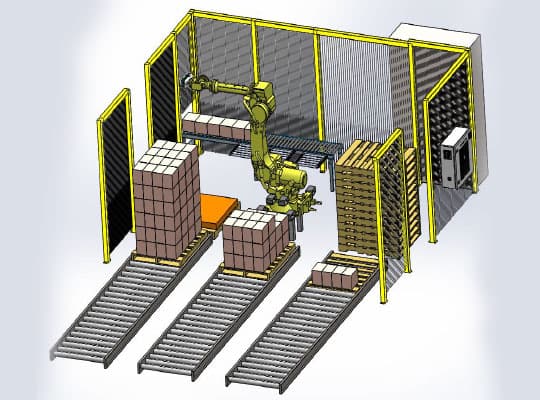

The systems are made up either with the conventional motion control / gantry-based systems or the latest, the robotic technologies.

Our esteemed customer list is not limited to

Carton Erector

Specifications

Power Requirements: 230V AC, 50 HZ, Single phase.

Air supply: Dry air at 4 bar 0.8 ltrs/cycle.

This machine can accommodate tape width of 3". An optional standard machine is suitable for tape width of 2.5”, 2”.

Standard tape roll length of 650 m and 1000 m can be used.

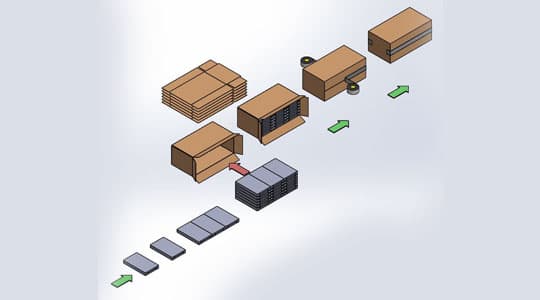

Case Packer

Side Loading of Boxes

Side loading case packer uses servo for precise case forming and indexing.

A gentle pack pattern collation system efficiently stacks product and loads cartons into cases while the next pack group is assembled.

Accurately handle a wide array of products in continuous motion.

Machine is designed specific to your application.

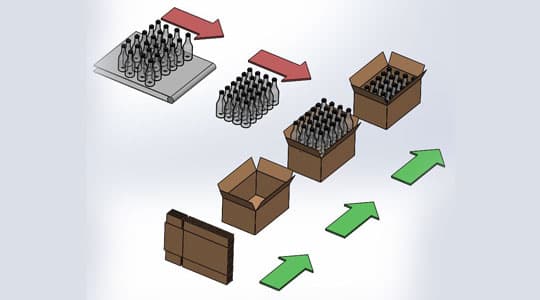

Top Loading of Bottles

Top loading case packer uses servo for precise case forming and indexing.

A gentle pick-and-place pack pattern collation system efficiently stacks product and loads cartons into cases while the next pack group is assembled.

Accurately handle a wide array of products in continuous motion.

Machine is designed specific to your application.

Pick & Place for Cartridges

About Pick & Place

The cartridges by means of imported vacuum grippers picks up and gently places on cartons.

Synchronization of the various machine operations is done by means of PLC.

Gripper head unit is having vacuum grippers to pick the product with the help of vacuum ejector.

The machine can run at variable speed.

Cartridge size: Dia 83* 500 long.

Matrix: 3*3

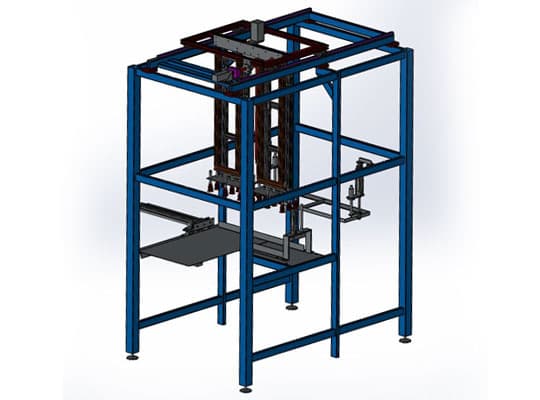

Pick & Place for Cartridges

About Pick & Place

Cartridge casing operation takes place by means of servo drive with X and Z movement with gantry system.

The cartridges by means of imported vacuum grippers picks up and gently places on cartons.

Synchronization of the various machine operations is done by means of PLC.

Gripper head unit is having vacuum grippers to pick the product with the help of vacuum ejector.

The machine can run at variable speed.

Cartridge size: Dia 83* 500 long.

Matrix: 3*3

Drum Palletizer

About Drum Palletizer

This is a "pick and place" Palletizer.

An automated machine that lifts metal/plastic from an in feed conveyor and carries them to a designated pallet.

A special vacuum mechanism is used to prevent any distortion of metal and plastic containers.

Rate: 100 per hour.

Load Capacity: 350kg/drum

Matrix Formation: 2*2

Suitable for various types of pallet.

Manual handling of drums is no longer required

Robot Gripper

About Robot Gripper

This vacuum grippers works gently & smoothly.

Number of suction cells: 15

Load Capacity: 350 N

Weight of Gripper: 1.67 kg

About Robot Gripper for bottles

Air gripper for bottle.

This air grippers works gently & smoothly.

Number of suction cells: 4

Load Capacity: 2.5 liter bottle

Weight of Gripper: 1.5 kg

Contact Us

Manufacturing Facility : HTKR PVT LTD , Umbharli Village , Dombivli Taloja Highway - 421204

info@htkr.in

9321666455

Socail Media

Contact Us

Manufacturing Facility : HTKR PVT LTD, Umbharli Village, Dombivli Taloja Highway - 421204

+91 9321666455

Social Media

HTKR PVT LTD 2026. All right reserved. | Powered by Aroopa Apps